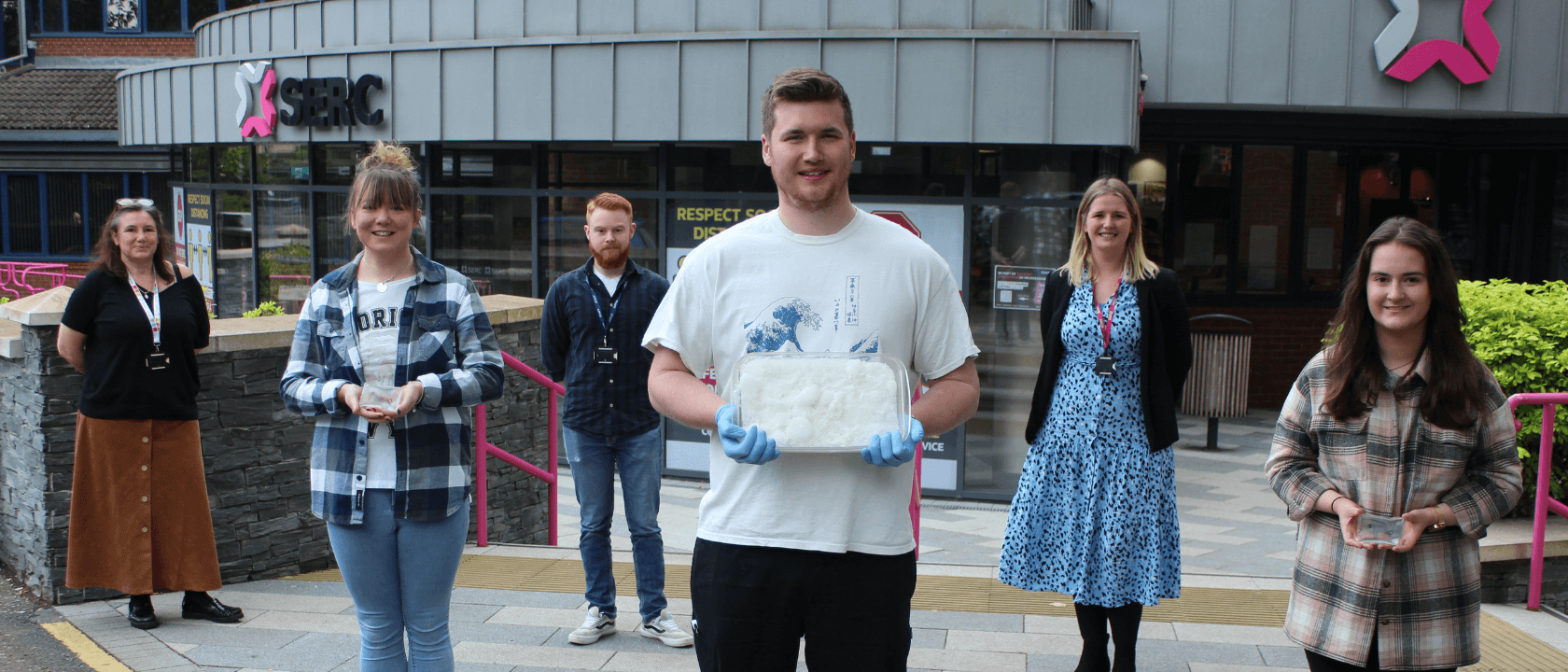

SERC & Crystal Air

About the Case – the challenge

Crystal Air Ltd had ambitions to create a new heat storage device to bring to market but lacked the in-house skills in product development of this nature including product design, rapid prototyping and quality inspection, and working experience of Computational Flow Dynamics (CFD) simulation and Computer Aided Design (CAD). The heat storage element of the project required expertise in Phase Change Material (PCM) which was completely new to the business. The project required collaboration between SERC’s Engineering and Science departments.

The Solution

Connected enabled SERC to work with Crystal Air and ultimately resulted in gaining innovation support from InterTradeIreland’s Innovation Boost programme. This enabled the company to design, develop, optimise and test a heat storage device and bring it to market.

SERC were able to work with Crystal Air and the Innovation Boost Graduate to implement:

Research and development to establish the best possible materials to maximise heat transfer

Material testing

3D Computer Aided Designs produced and simulated using CFD

Market research for expansion of the new product

New PCM heating sphere has been developed and is ready to bring to market